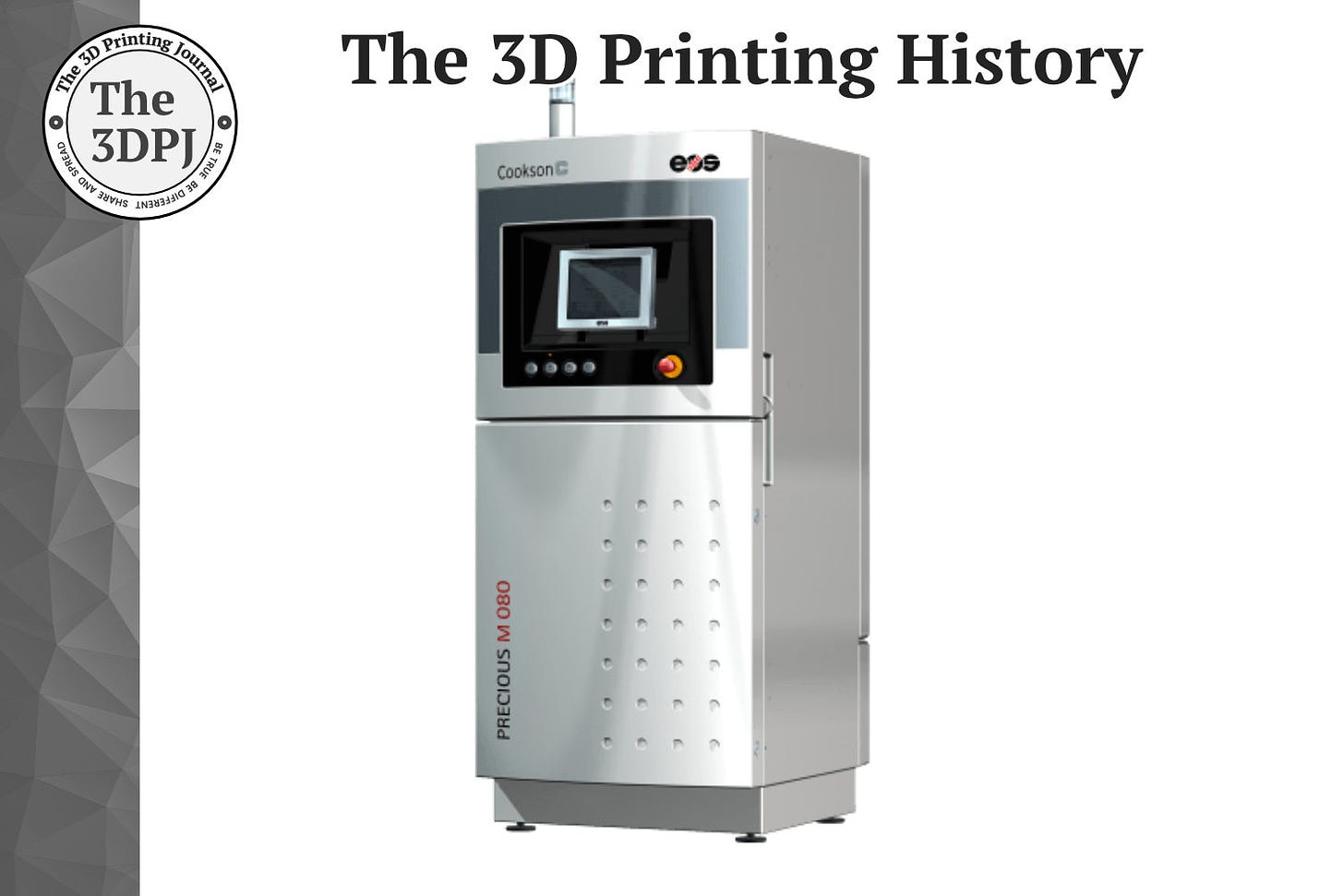

09-15-2014: EOS & Cooksongold officially announced the launch of the PRECIOUS M 080 Jewelry DMLS 3D printer

The 3D printer is discontinued

On September 15, 2014, EOS – a German manufacturer of 3D metal printers, and Cooksongold, a UK supplier of fabricated precious metals, announced the launch of the PRECIOUS M 080 Direct Metal Laser Sintering system at the Hong Kong Jewellery and Gem Fair 2014. The new system was intended to be an affordable, compact, and design-driven manufacturing solution for the production of watch and jewelry products.

Unfortunately, despite considerable media buzz at the time of its debut, the machine did not stand the test of time and was withdrawn from the market. Official statements on the matter were scarce.

The 3D printer was equipped with a 100-watt fiber laser, designed to meet the needs of the jewelry and watch industry. It had an 80 mm diameter round build platform with a working stroke of 95 mm high (including the building platform). The metal powders produced by Cooksongold were optimized to match the performance of the Precious M 080 system.

The 3D printer could produce parts using a variety of gold alloys, and there were plans for the future development of additional materials to meet customer demands.

3D printing with precious metals is difficult to achieve for three main reasons:

High reflectivity and thermal conductivity – Absorbing laser energy during the powder sintering process is challenging, which can lead to uneven melting and difficulties in controlling the process.

Material cost – Any material loss, such as during testing or due to printing errors, is much more expensive than with standard metals.

Powder atomization – This complicates material production and processing. Fine powder is also more prone to oxidation and harder to control during the printing process, increasing the risk of defects in the final parts.

These factors, along with the "typical resistance" of industries to the rapid adoption of additive manufacturing, contributed to the fact that despite its intriguing possibilities, the Precious M 080 did not become a commercial hit and was eventually discontinued. In some ways, the machine was ahead of its time. Today, with a much higher degree of 3D metal printing adoption, as well as new, relatively affordable methods of metal alloy atomization, this machine might have had a better chance…

Source: www.3ders.org

I purchased one of the product made out of silver from Boltenstern and I believe it is printed by cooksongold. I was so curious the quality of precious metal and choose one product and received. M80 makes sense for precious metal as their spot size/ build platform / cartridge system at least most friendly system. Most recently I have seen several used M80 machine deal and cooksongold is move to binderjet. In this specific category still 3d printed wax and casting makes sense instead of direct manufacturing.