10-28-2021: Raise3D launched MetalFuse – a comprehensive 3D printing solution for metal filament from BASF

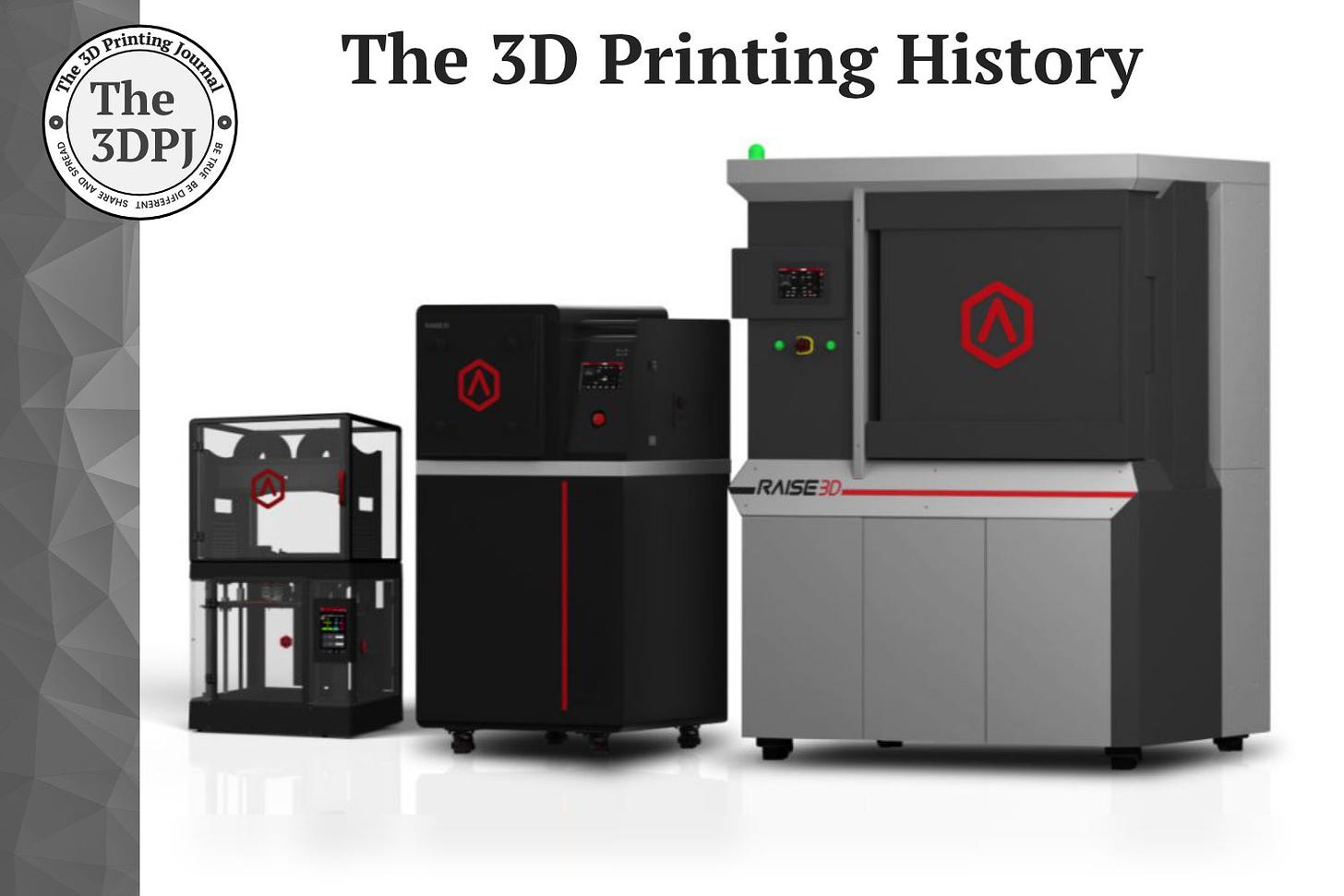

System comprised the Forge1 3D printer, the D200-E catalytic debinding furnace, and the S200-C sintering furnace

On October 28, 2021, Raise3D – a manufacturer of FFF 3D printers – announced the debut of its new 3D printing system, Raise3D MetalFuse. This system was a fully integrated ecosystem for 3D metal printing, developed in close collaboration with BASF (now Forward AM) for Ultrafuse Metal Filaments. The primary applications for printed parts included tooling for machinery and production lines, functional parts and prototypes, and low-volume production.

The Raise3D MetalFuse system comprised the Forge1 3D printer, the D200-E catalytic debinding furnace, the S200-C sintering furnace, the ideaMaker Metal 3D printing software, and the Ultrafuse Metal Filaments (BASF) Forward AM materials.

The ideaMaker Metal software was a modified version of ideaMaker, optimized for the Ultrafuse Metal Filament and featuring unique functionalities to ensure the required density and repeatability, producing high-quality end-use parts.

The D200-E furnace utilized a catalytic debinding process with oxalic acid, commonly used in MIM technology, which is both safe and environmentally friendly. Meanwhile, FDM/FFF technology provided complete design freedom, enabling the production of complex parts that would otherwise be prohibitively expensive or impossible to produce via MIM.

According to Raise3D’s internal testing, catalytic debinding reduced process time by 60%, increased part density to 98% of forged iron density, and achieved a 52% increase in yield strength compared to the solvent debinding method.

Starting in the first half of 2022, Raise3D initiated large-scale global deliveries of the MetalFuse system through selected commercial partners. The Forge1 3D printer has also been made available to customers who have their own capabilities for debinding and sintering materials.

Source: www.raise3d.com