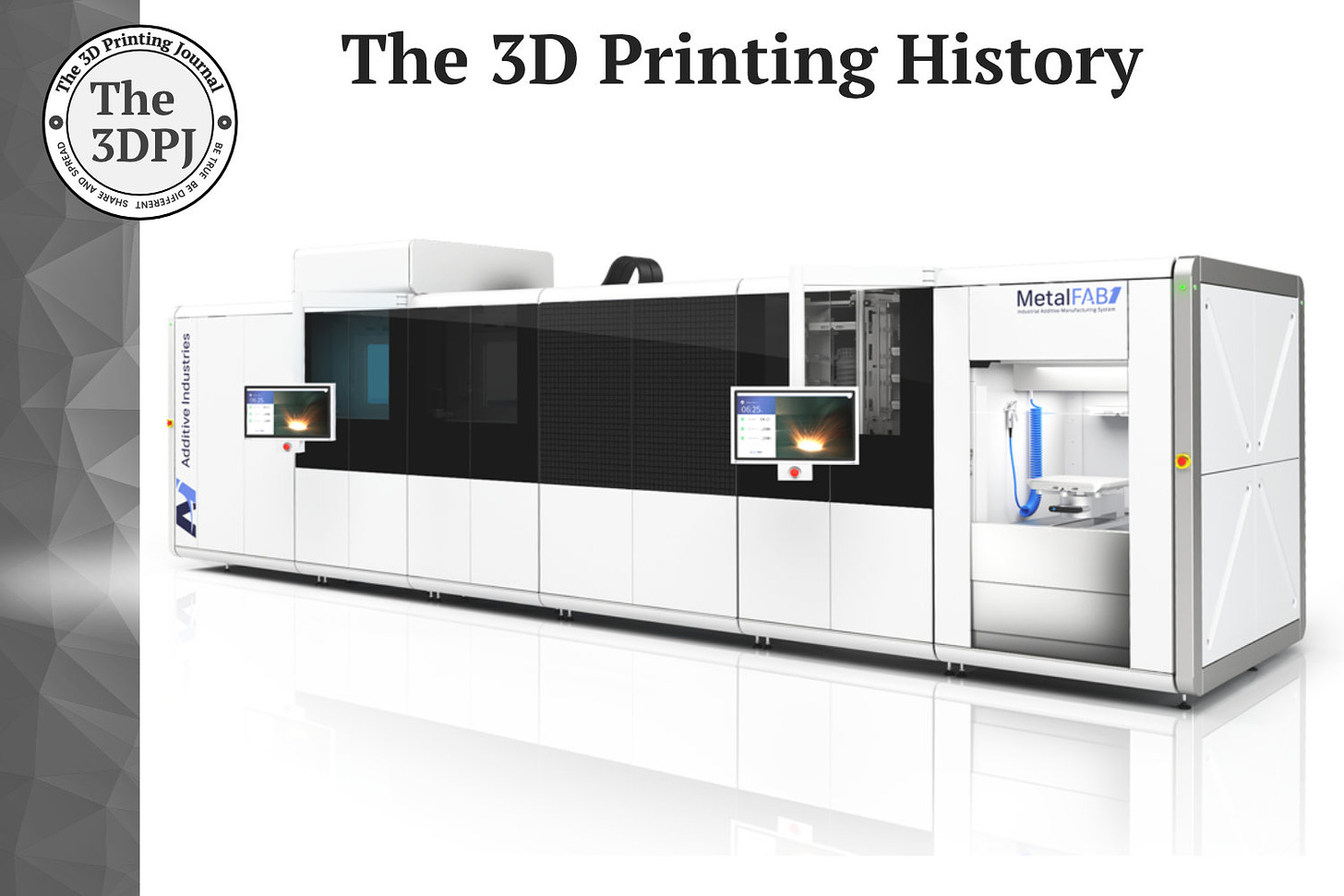

11-16-2015: Additive Industries unveiled its first modular metal AM system - the MetalFAB1

It allowed users to customize the system configuration to specific needs

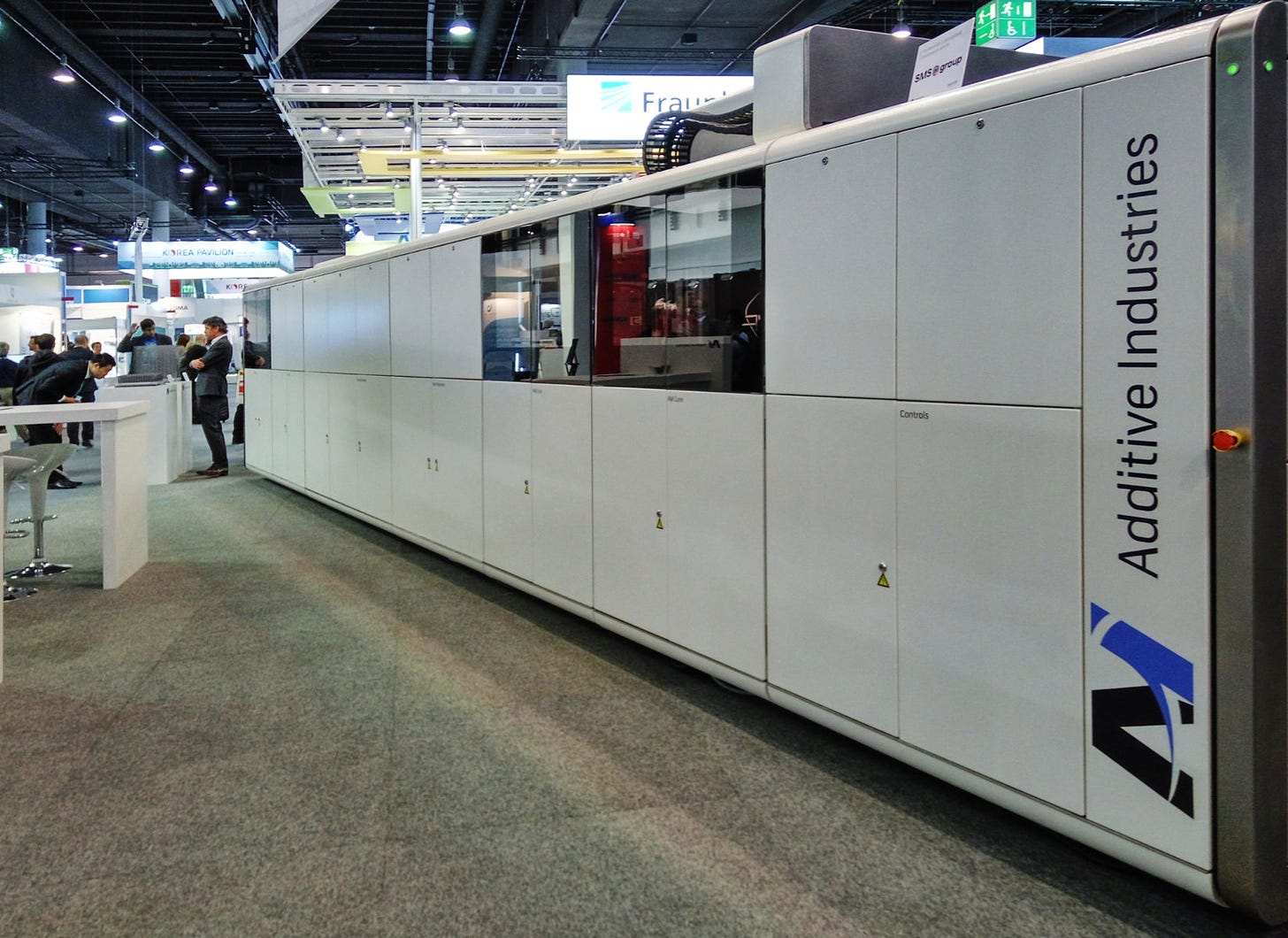

On November 16, 2015, the Dutch company Additive Industries introduced the MetalFAB1, the first modular system designed for 3D metal printing using LPBF technology (Laser Powder Bed Fusion). The launch took place in Eindhoven, Netherlands, where the company is headquartered. MetalFAB1 was developed with a focus on automation and integration of production processes, aiming to enhance efficiency and repeatability for industrial applications.

Additive Industries was founded in 2012 by Jonas Wintermans and Daan Kersten in Eindhoven, located in the heart of the Brainport region, renowned for its advanced technology and electronics industries. The company specializes in industrial 3D metal printing, utilizing the Laser Powder Bed Fusion method for selectively melting metal powders.

The MetalFAB1 featured a modular design, allowing users to customize the system configuration to specific needs. The system could be expanded from three to eleven modules, enabling users to scale production based on demand. Additionally, the printer supported up to four full-field lasers, significantly speeding up the printing process and allowing for the simultaneous production of multiple components.

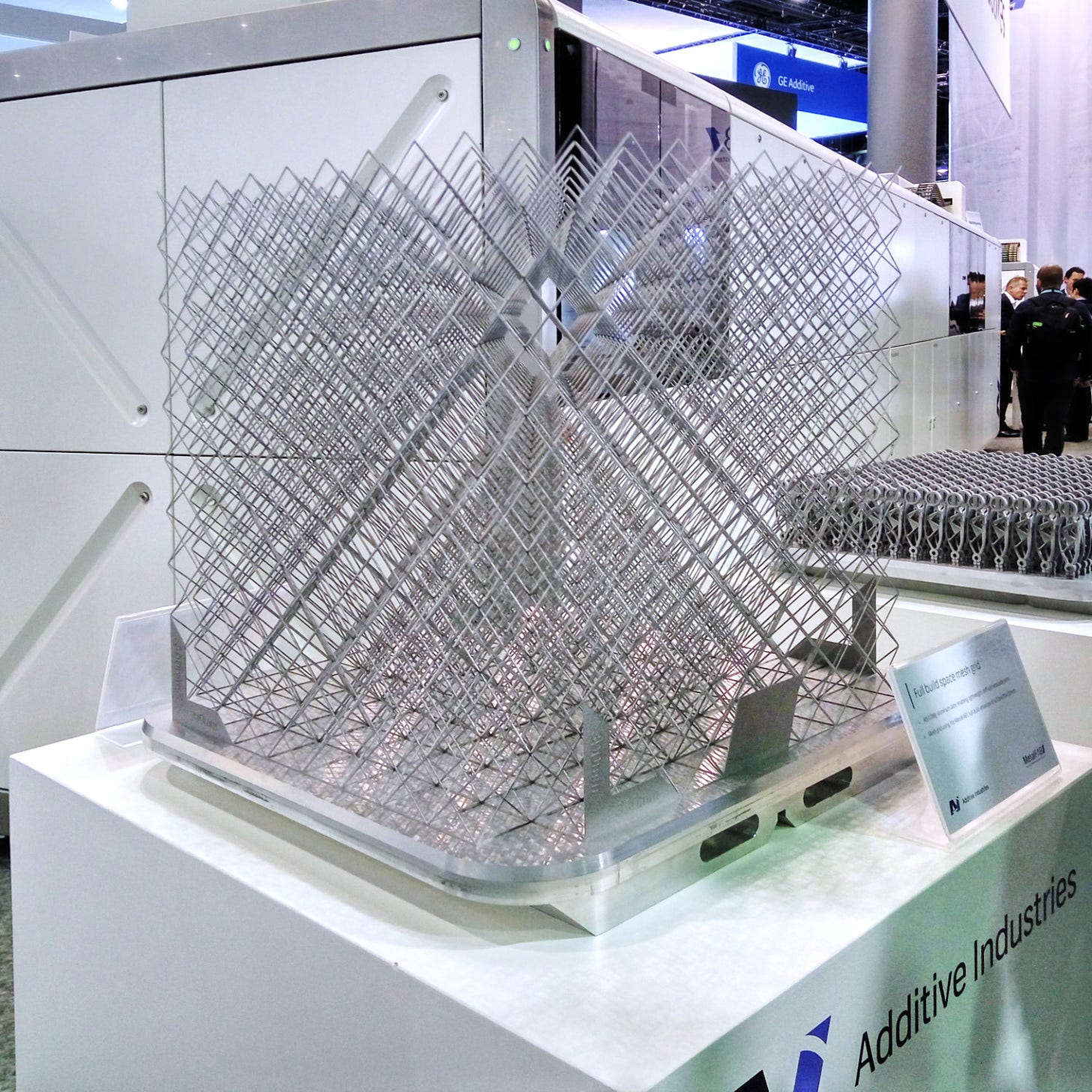

The system offered a build volume of 420 x 420 x 400 mm, accommodating the production of large components or multiple smaller parts in a single cycle. A key feature of the MetalFAB1 was its integrated heat treatment processes. The system included a built-in furnace for stress relief, eliminating the need for separate equipment.

It also boasted advanced automation, including automated powder sieving and build plate handling. These features minimized operator contact with materials, enhancing workplace safety. The modules were designed to handle a variety of metal powders, including titanium and aluminum, while dual-core technology allowed for the use of different materials without the risk of cross-contamination.

Source: www.hubspot.net