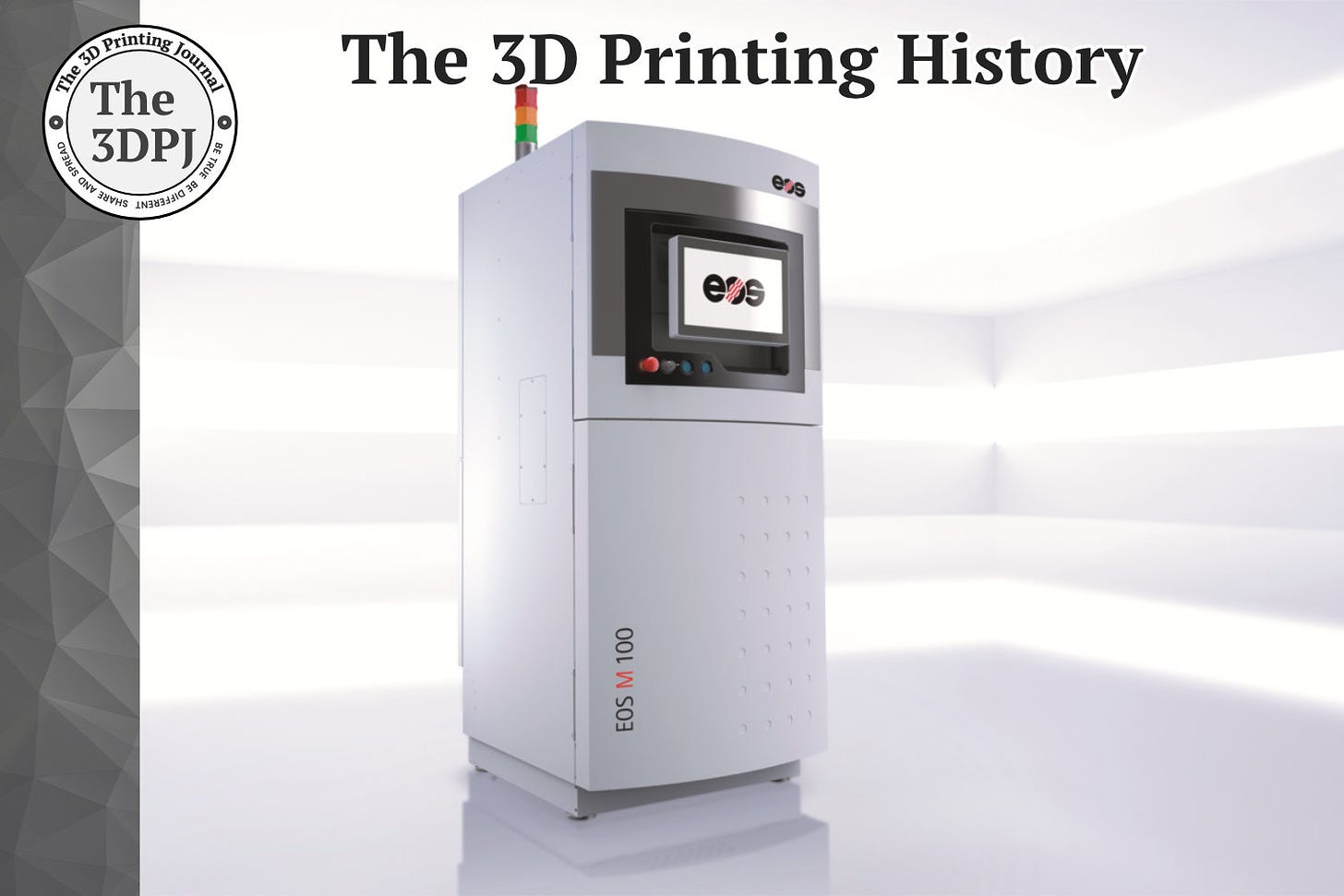

11-17-2015: EOS launched its smallest, compact 3D metal printer – the M 100

Unfortunately, the 3D printer has already been expired

On November 17, 2015, EOS introduced its smallest 3D metal printer, the EOS M 100, during the inaugural edition of the Formnext trade show in Frankfurt. The device was designed as a compact and cost-effective solution for companies starting with Direct Metal Laser Sintering (DMLS) technology. The EOS M 100 was ideal for producing small batches of high-quality components.

The EOS M 100 offered a build volume of 100 mm in diameter and 95 mm in height. It was equipped with a 200-watt fiber laser, delivering high power stability and excellent beam quality. Thanks to its small laser spot diameter (40 µm), the printer enabled precise production of intricate and delicate parts, such as dental crowns and bridges.

The device featured a modular internal design, simplifying material changes, maintenance, and preparation for operation. Its fast recoating technology and optimized exposure strategies minimized downtime, increasing production efficiency. The maximum power consumption was 1.7 kW, while the average consumption was only 0.6 kW, making the EOS M 100 highly energy-efficient.

The 3D printer was compatible with materials such as EOS CobaltChrome SP2 (used in dental prosthetics) and EOS StainlessSteel 316L (applied in medical devices, aerospace, and consumer products). Support for EOS Titanium Ti64, dedicated to the automotive and biomedical industries, was also planned.

One of the standout features of the M 100 was its ability to produce approximately 70 dental crowns in just three hours, making it an efficient solution for small-batch production and an excellent choice for dental laboratories.

Unfortunately, the EOS M 100 has since been discontinued as the company shifted its focus to larger machines, including the flagship EOS M 290 and M 400 models, which offer broader production capabilities and support for more advanced materials.

Source: www.metal-am.com